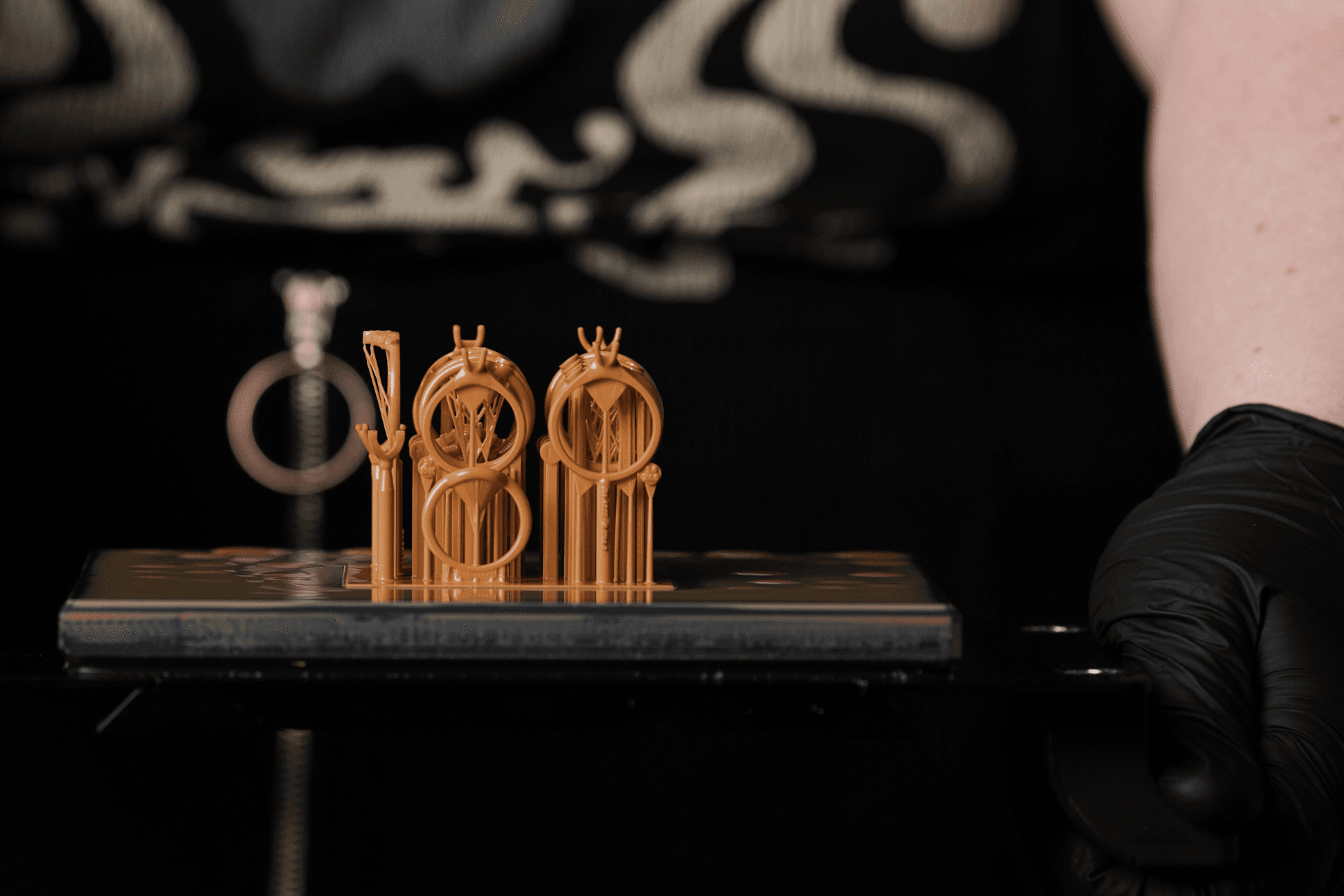

Since 1947, we've been at the forefront of the jewellery industry. Today - our high-resolution printers enhance traditional craftsmanship, delivering consistent and accurate prototypes that are meticulously prepared for casting.

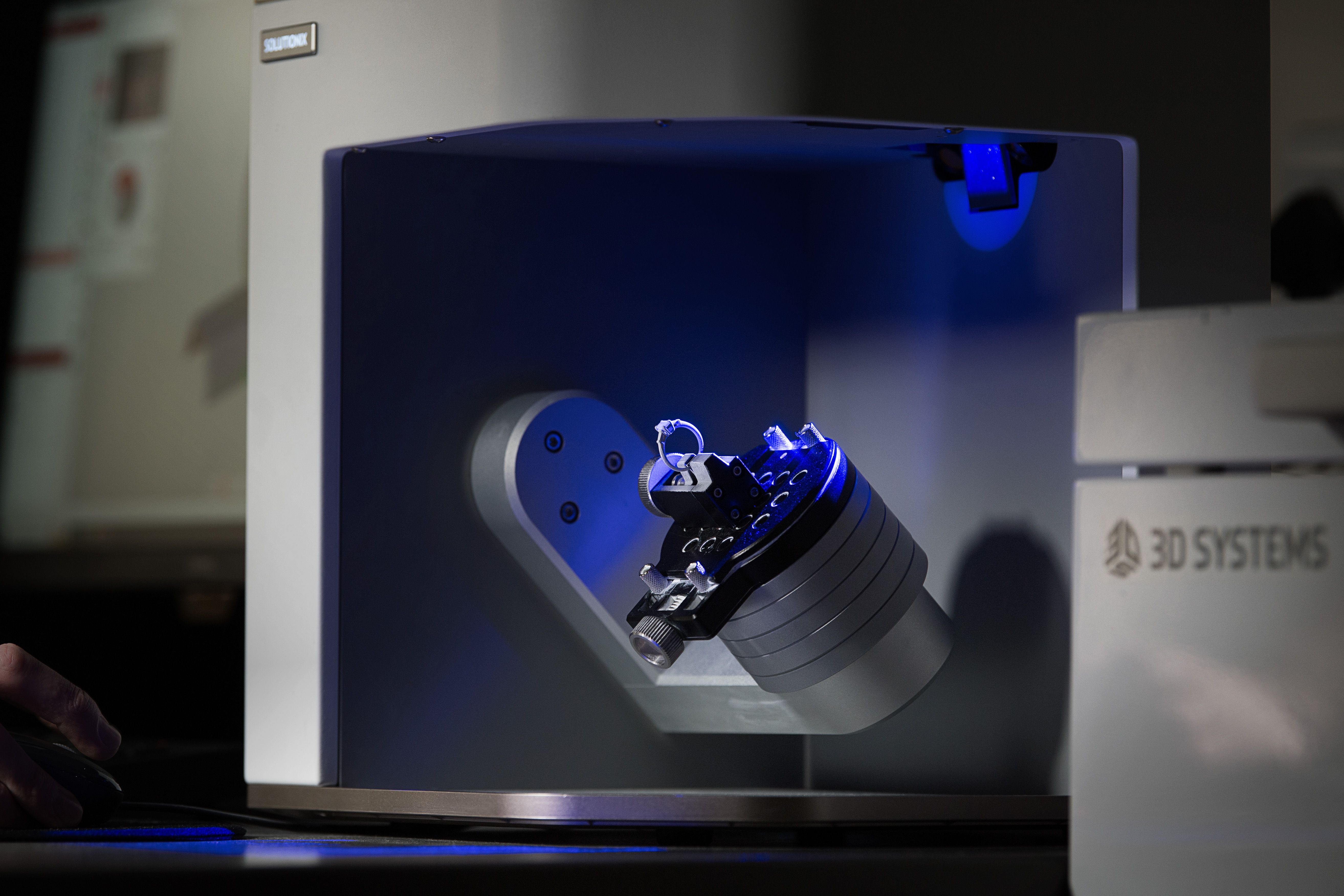

Our industry-leading in-house facility, equipped with multiple advanced machines, is one of the largest in the UK and operates daily to move your designs from concept to reality. We offer a choice of print materials to precisely match your needs, with resins and waxes for prototypes, customer evaluation or direct to casting.

By integrating 3D printing directly into our full in-house service, your project moves efficiently from a digital file to a finished piece—seamlessly flowing from CAD to printing, casting, and hallmarking, all under one roof.

Get in touchWhy Choose Weston Beamor for 3D Printing?

Integrated Innovation

We don't just print - we integrate. Our solutions combine traditional craftsmanship with advanced digital tools, ensuring a seamless journey from file to finished piece.

Expert Pre-Print Analysis

Before we move your design into production, every file is carefully reviewed by our team of experts. This step highlights any potential issues and makes sure your model is optimised for successful casting.

Widest Choice of Alloys

Once your design is approved, we move it seamlessly from print to cast. From fairtrade alloys to SMO gold and recycled materials, we offer one of the widest choice of alloys in the UK to provide you with an extensive range of options.

Guaranteed Quality & Service

In the rare event that one of our 3D prints fails during the casting process, we offer complimentary reprinting and recasting, keeping your schedule on track and your costs predictable. We also offer mould setup as part of our service.

Our 3D Jewellery Printing Process

Our structured, reliable process is built to capture and produce fine detail, delivering casting-ready 3D prints that seamlessly integrate into your manufacturing workflow.

Step 1 Consultation & Assessment

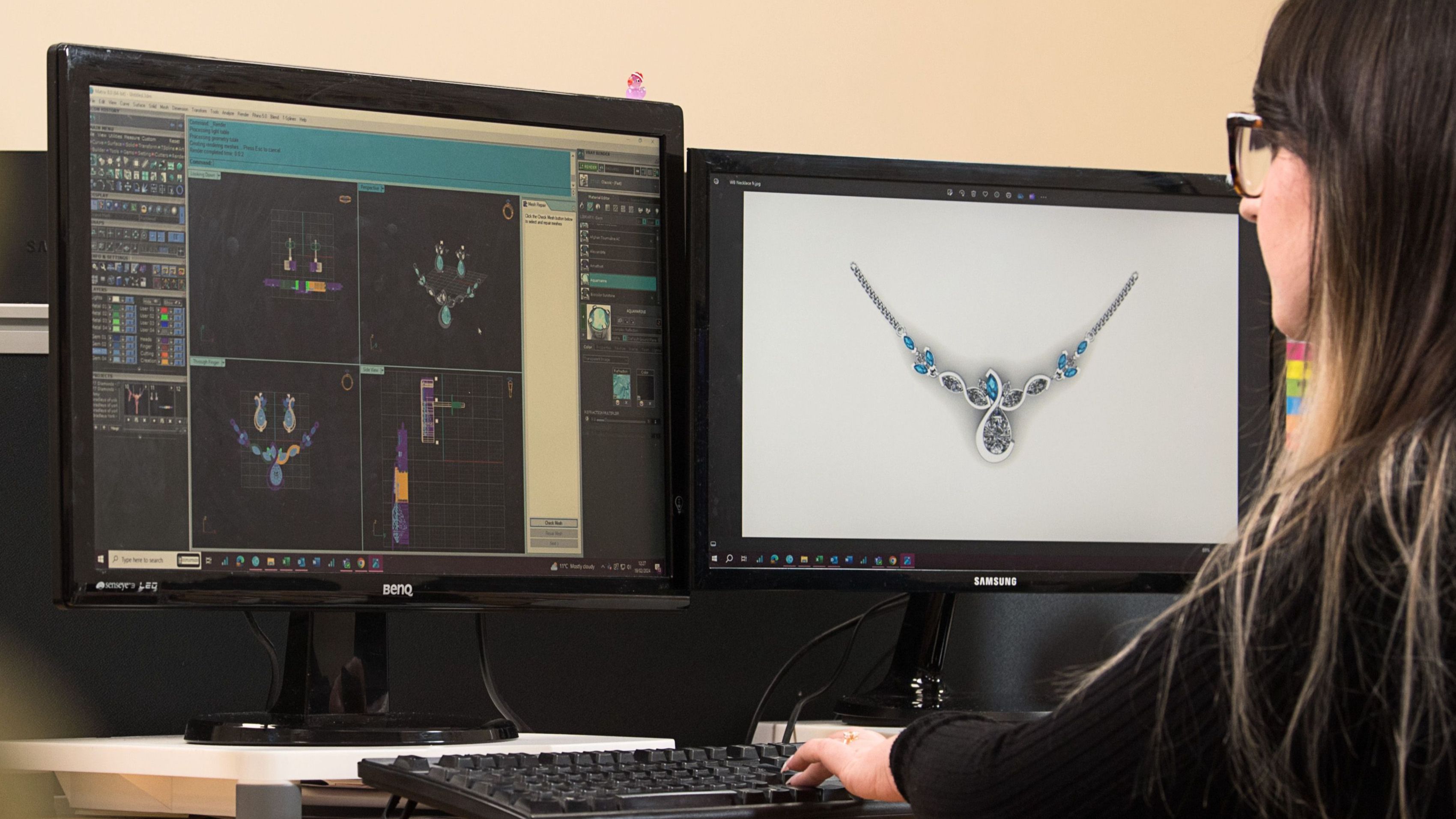

We begin by understanding your project’s needs. Files are reviewed and optimised for print readiness and castability, with expert guidance from our team throughout.

Step 2 Material Selection & Printing

Working with you, our team ensures every print is optimised for accuracy, surface quality, and the best possible casting outcome.

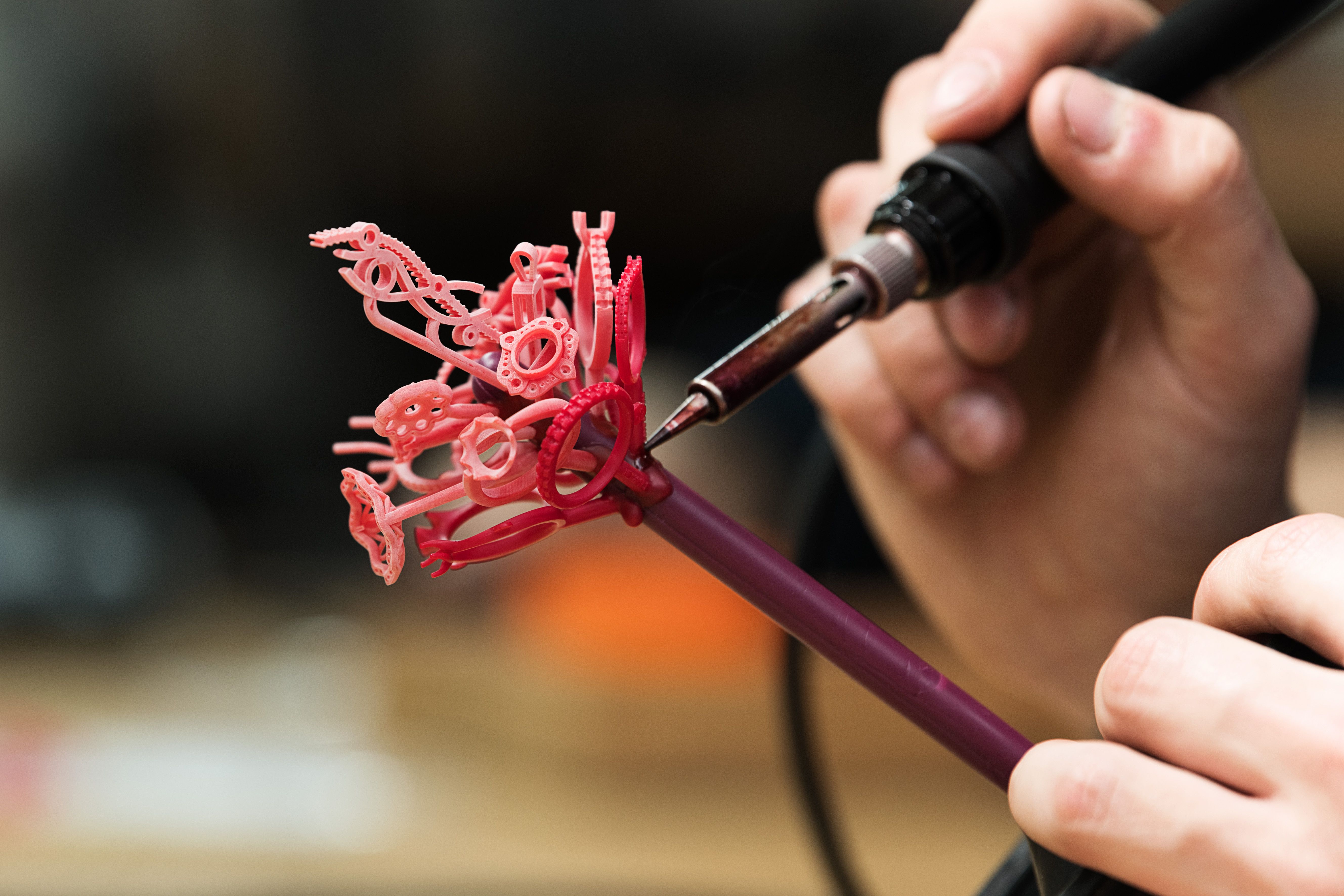

Step 3 Post-Processing & Quality Check

Printed models undergo careful post-processing and thorough quality checks to ensure dimensional accuracy and a flawless surface finish before casting.

Step 4 Casting & Integration

With the print approved, our team ensures it’s perfectly prepared for casting, seamlessly integrating your 3D prints with Weston Beamor’s full suite of in-house manufacturing capabilities.

Get in Touch

Our in-house capabilities include

- Wax Printing to Cast: ideal for one-off pieces and limited runs or anywhere high precision is essential to the design, as well as pieces with complex geometry.

- Resin Printing to Cast: A ceramic-based material ideal for cold-cure moulding to create a repeatable model

- High-Resolution Wax Printing: A suite of machines that deliver smooth surfaces meticulously prepared for fine jewellery production.

- Direct to Mould Wax Casting: Perfect for repeatable designs.

- Precious Metal Casting: We have spent years honing our craft, casting in gold, platinum and silver, with tried and tested results across direct printed wax and waxes generated from a mould.

Discover Our Full Range of Services

Beyond 3D printing, Weston Beamor offers a comprehensive suite of services to support your jewellery production needs, from initial concept to final finish:

- Design: Bring the vision for your bespoke and full ranges to life with our expert jewellery design services, from initial sketches to full 3D renderings.

- 3D Scanning: Accurately replicate existing pieces or physical models into digital files for further modification or reproduction.

- Casting: Utilise our advanced casting facilities for high-quality metal casting in gold, silver, platinum and brass.

- CAD Modelling: Develop precise and intricate jewellery designs in a digital environment, ensuring accuracy and efficiency in production.

- Manufacturing & Production: From one-offs and small batches to full collections, our manufacturing team delivers consistent quality and dependable turnaround, turning your designs into finished pieces.

- Finishing: Whether you’re after a high-shine polish, a satin texture or something more specialist, we apply care, consistency, and attention to detail.

- Hallmarking: As a Weston Beamor customer, you can take advantage of our on-site sub-assay office provided by Birmingham assay office when you cast with us.

Our Services

Speak To Our 3D Printing Experts

Our state-of-the-art technology enhances, not replaces, traditional craftsmanship. It is the foundation of a streamlined workflow that delivers consistency, precision, and efficiency for every project, from one-off bespoke pieces to full-scale collections. Get in touch with our team of jewellery experts today to see how our 3D printing capabilities can boost your jewellery manufacturing processes.

FAQ's

What is 3D Scanning?

3D scanning is the process of capturing an accurate digital version of an existing jewellery piece, typically used to replicate, modify or design complementary items such as shaped wedding bands.

What materials do you print in?

Mouldable Resin and Direct Cast Wax

What is 3d printed jewellery?

3D printed jewellery refers to wax or resin models of jewellery that have been produced using high-resolution 3D printing technology. These models are then used for casting into metal or for creating silicone moulds.

What if my print fails during casting?

We’ll reprint and recast at no extra charge, helping keep your schedule on track.

Do you offer bulk printing for collections?

Absolutely. Our print facility supports everything from one-offs to small batch runs and full-scale production.