Advanced 3D Jewellery Scanning

Our advanced 3D scanning capabilities create flawless digital archives that allow for the reverse-engineering of a single piece with absolute accuracy.

This technology captures even the most intricate details, providing a seamless bridge from your physical jewellery to its digital twin, ready for the next stage of production. We can also adapt these processes for bespoke commissions, ensuring every unique piece is captured with the same level of fidelity.

For retailers, brands and designers seeking consistency and quality, our 3D jewellery scanning service is the ideal solution. It generates the precise, high-accuracy data required for our in-house teams to seamlessly move your design from CAD to casting, mounting, stone setting, and final hallmarking, all under one roof.

Where necessary, scanning is integrated into our broader manufacturing workflow to ensure a controlled, efficient, and reliable journey for every piece you create.

3D Jewellery Scanning You Can Rely On

Choosing to 3D scan jewellery with Weston Beamor allows you to reproduce complex designs that would be incredibly challenging to replicate by hand. It provides you with a more streamlined and controlled process, from initial ideation to final creation.

Whether you’re looking to create a shaped or fitted wedding ring, capture a wax model for casting, replicate items at scale, or duplicate an existing piece, our 3D jewellery scanning technology makes the process easy and supports every project through to metal.

Our team provides a tailored service, using professional-grade jewellery scanners and offering expert guidance with seamless integration into your business.

Get in touch

Unrivalled Expertise

Partner with a team of experts who guide you through every step, from scanning and manufacturing to administration and final delivery.

Flexible CAD Services

We seamlessly integrate with your creative workflow, offering scalable solutions for everyone from independent designers to global jewellery brands.

Fast, Scalable Production

Our scanning service digitises your pieces for fast-tracked CAD amends and casting, enabling you to respond to market trends with speed and accuracy.

Cost Efficiency

With all processes handled under one roof, we streamline the entire journey from scan to production. This integrated approach helps you scale your business efficiently while maintaining the quality and integrity of your designs.

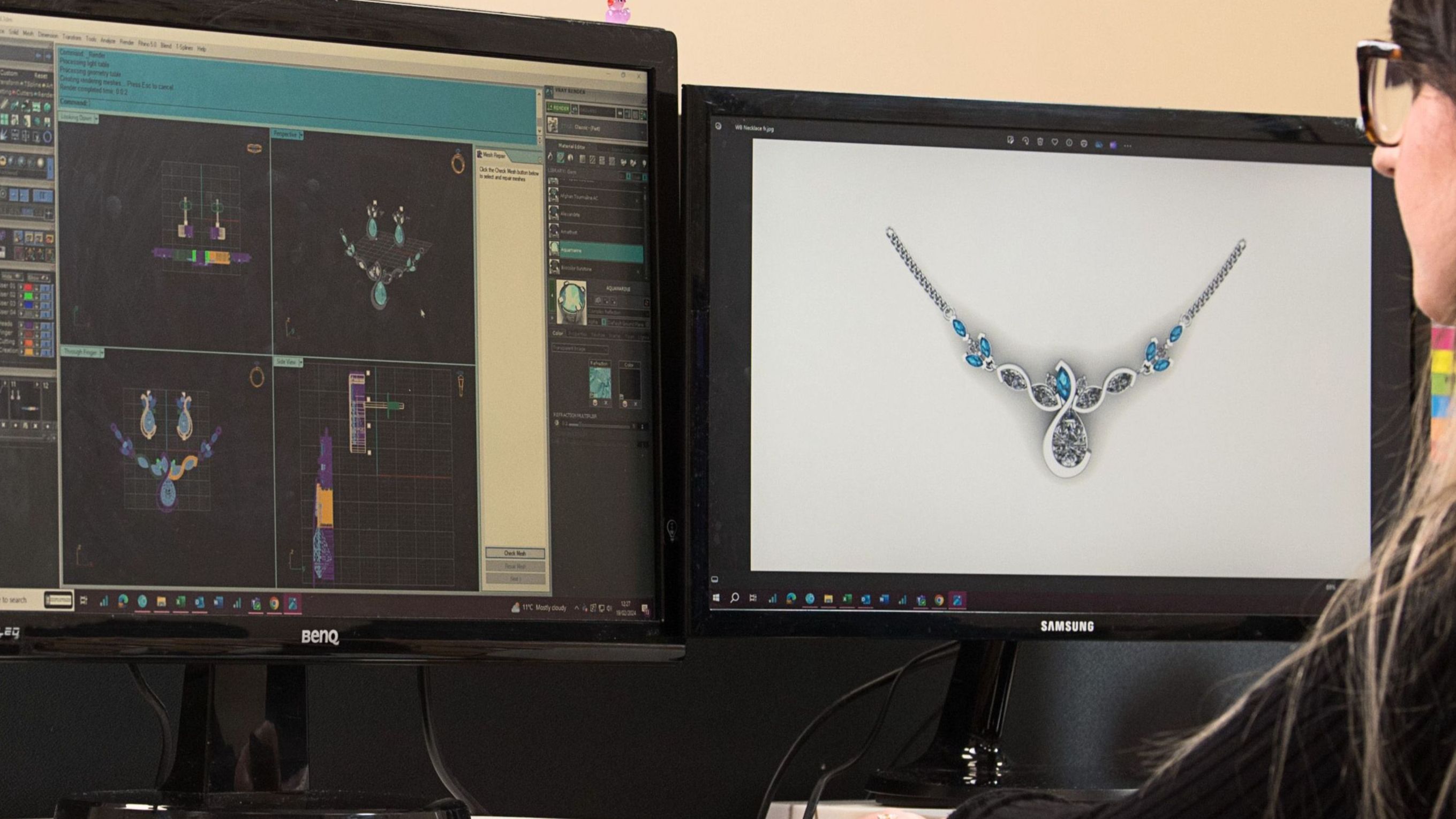

Design

Our 3D scanning service works closely with our in-house design team. Whether it's a bespoke one off piece or a full collection, we use the scanned data to develop accurate CAD models. This makes sure every piece captures your vision and is production-ready from the outset.

What Is 3D Jewellery Scanning?

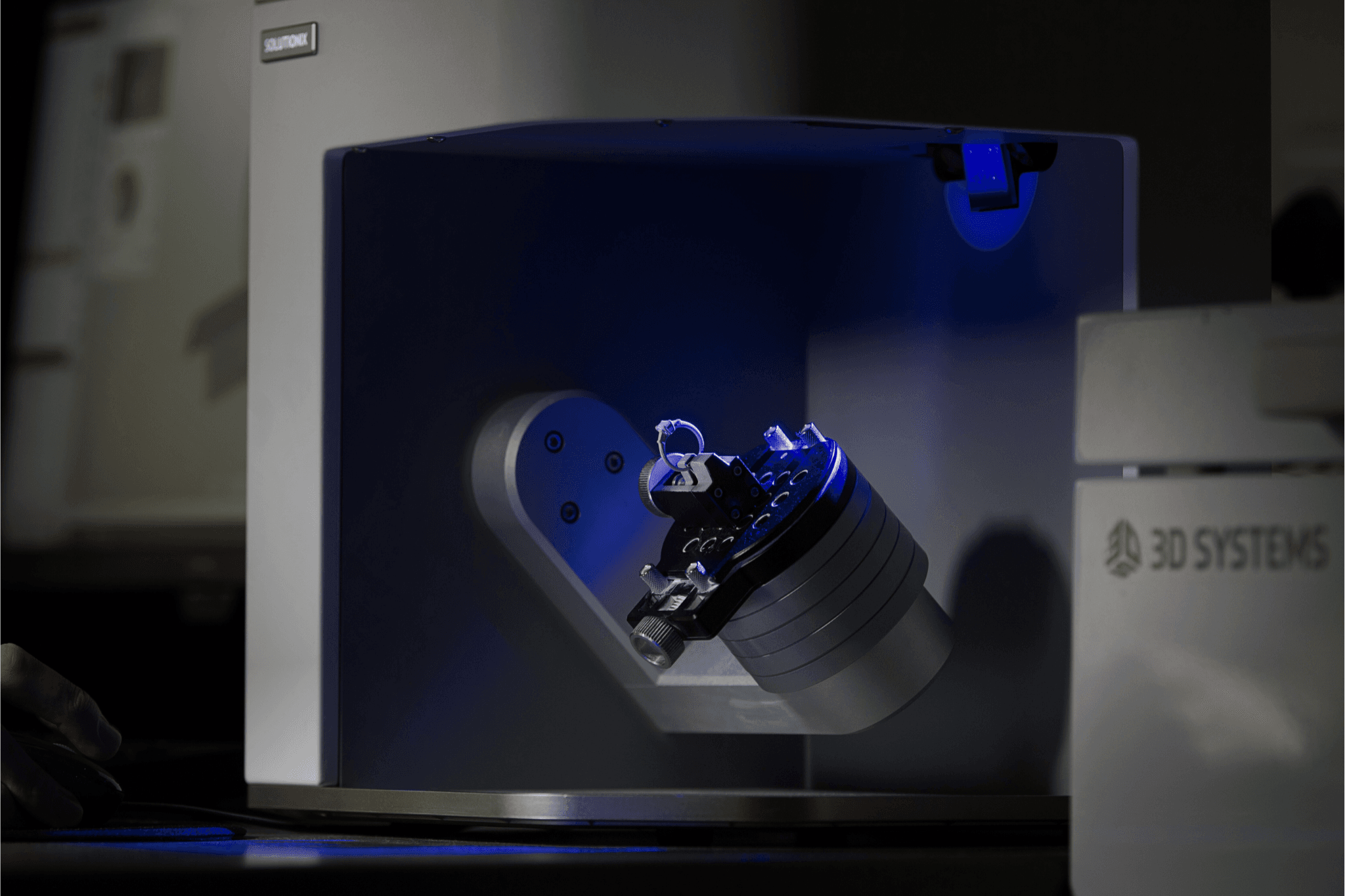

3D jewellery scanning is the definitive method for creating precise digital replicas of physical jewellery. We employ state-of-the-art, high-resolution technology to digitise items and convert them into highly accurate, editable STL files.

These digital files are imported into our CAD software, granting our designers the flexibility to amend, personalise, or completely transform a scanned piece to create a finished product for you.

Whether you're refining a classic wedding band or customising a customer's heirloom, 3D scanning enables faster, more flexible, and more accurate production. This technology minimises the need to handle original pieces and elevates design precision, seamlessly integrating traditional craftsmanship with cutting-edge digital design.

This process is also integral to our shape-to-fit service, where we ensure a flawless connection between two separate pieces of jewellery. By scanning your existing jewellery, we can digitally model a matching piece or pieces that follow the exact contours of the original.

This guarantees a perfect fit for bespoke wedding and eternity bands, creating a seamless and beautiful union that traditional methods often can't achieve.

Get in touch

Our 3D Scanning Process

Consultation

From one-off heirlooms to scaled production, we offer advice on scanning suitability and, for those less familiar with CAD, jargon-free guidance throughout.

Scan

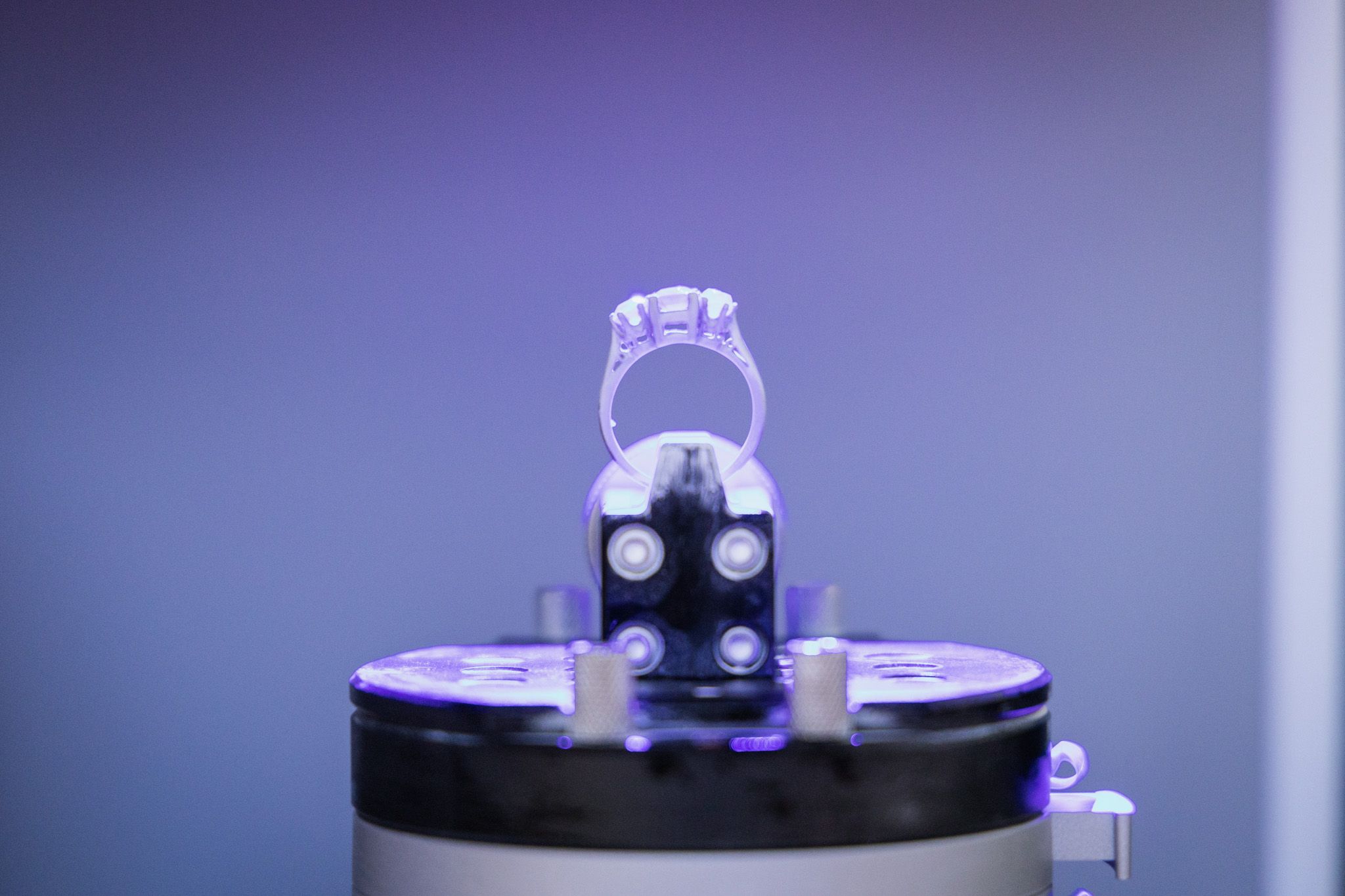

We utilise industry-leading 3D scanning technology to create an accurate, non-destructive digital model of your item. This process is perfect for delicate pieces like engagement rings or antique jewellery.

File Delivery

Your item is converted into an editable STL file, compatible with any CAD software. This file is used by our in-house team to create bespoke metal pieces.

Casting Services

Our in-house 3D printing team takes your 3D jewellery scan and professionally kickstarts the production process, ensuring a smooth transition from digital file to final product.

Discover Our Full Range of Services

Beyond 3D Scanning, Weston Beamor offers a comprehensive suite of services to support your jewellery production needs, from initial concept to final hallmarking:

- Design: Bring the vision for your bespoke and full ranges to life with our expert jewellery design services, from initial sketches to full 3D renderings.

- 3D Printing: Rapidly create highly detailed prototypes and master patterns in a variety of materials using cutting-edge additive manufacturing.

- Casting: Utilise our advanced casting facilities for high-quality metal casting in gold, silver, platinum and brass.

- CAD Modelling: Develop precise and intricate jewellery designs in a digital environment, ensuring accuracy and efficiency in production.

- Manufacturing: Benefit from our extensive manufacturing capabilities, turning your designs into tangible, high-quality jewellery pieces.

- Production: From one-offs and small batches to complete ranges, our efficient production processes ensure consistent quality and timely delivery.

- Finishing: As part of our in-house process, we provide expert finishing with care, consistency and attention to detail, from high-shine polish to satin textures.

- Hallmarking: As a Weston Beamor customer, you can take advantage of our on-site suboffice provided by Birmingham assay office when you cast with us.

Get in touch

Speak to our 3D Scanning and Design experts today

Launching a new collection? Replicating a timeless piece for one of your customers? Get in touch with our team today to discuss our 3D jewellery scanning services.

Get in touch