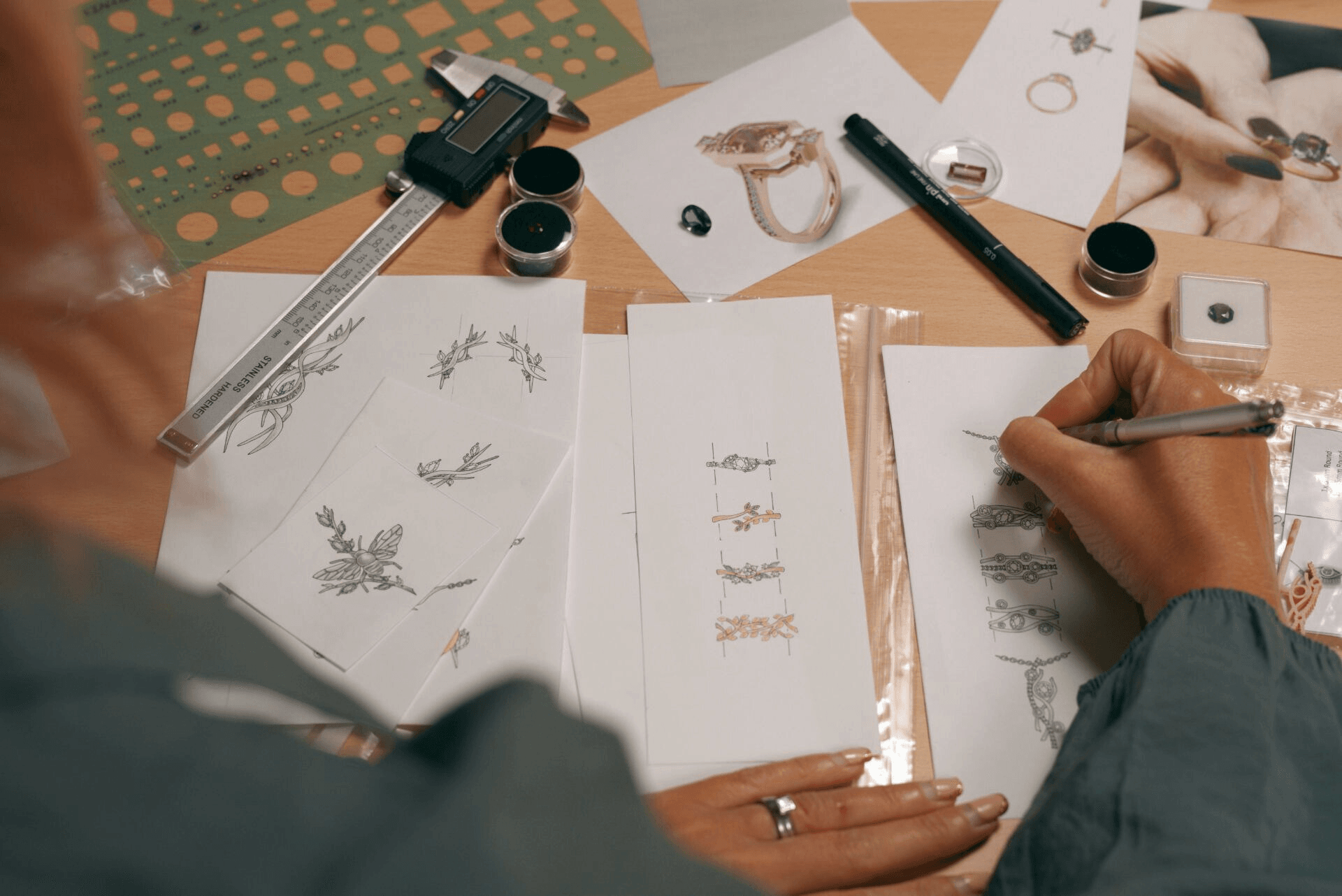

Bespoke Hand-Drawn Jewellery Designs

Our in-house design team creates incredibly detailed, hand-drawn sketches with a variety of design options for each bespoke project, so every project is tailored to your and your customers' needs.

As part of our wider casting and bespoke manufacturing solutions, our designers are skilled in creating designs that let creativity flow whilst also ensuring practicality for manufacturing - helping you create a smooth, seamless process.

Get in touch

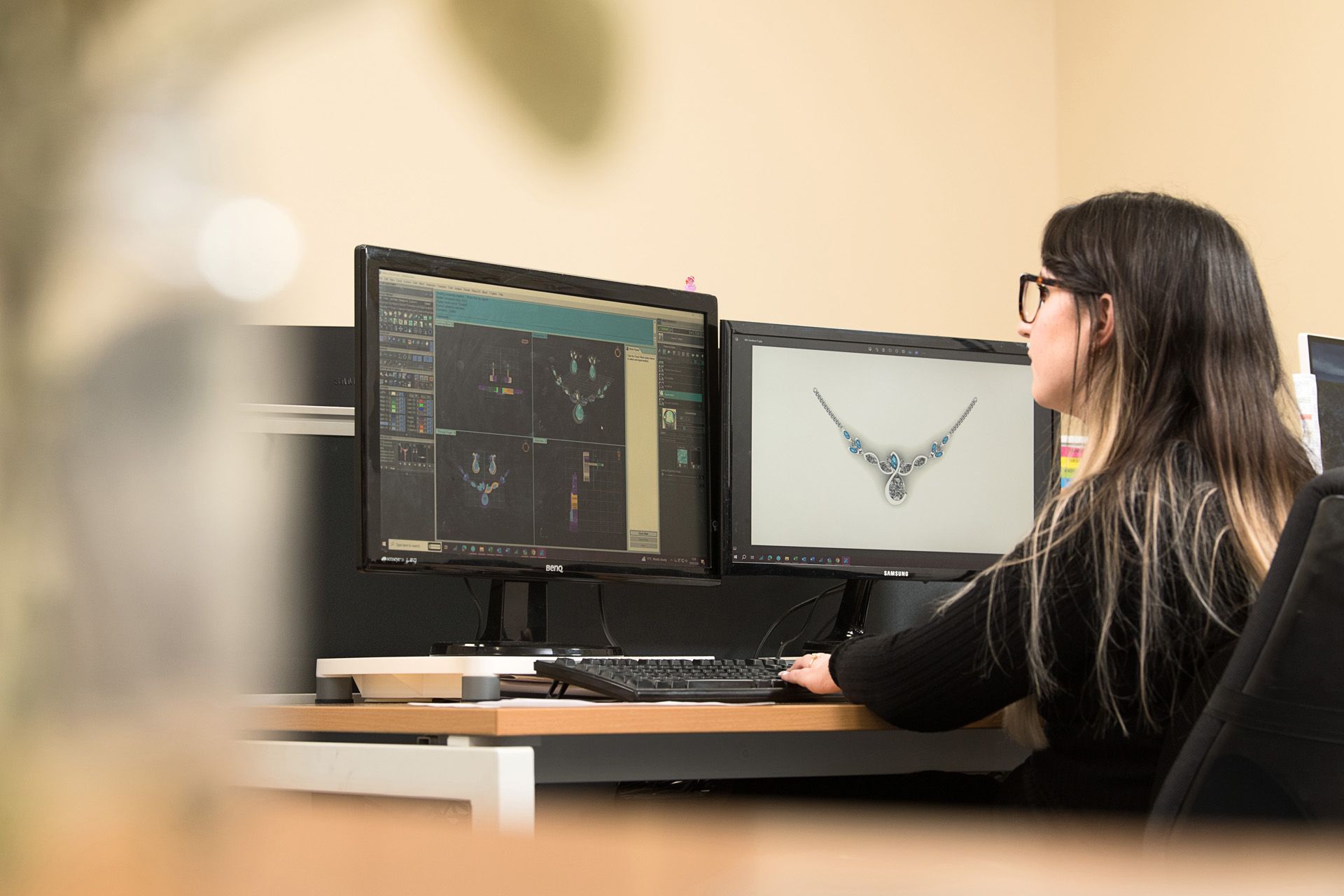

CAD Design for Jewellery: Turning Ideas into Reality

Whether you opt for hand drawn or 3D renders as your starting point, our experienced CAD team always make sure your designs are production-ready and are created with detail and accuracy. When you’re ready to get started, we’ll share high resolution renders and 3D models for approval before moving to casting and full manufacturing.

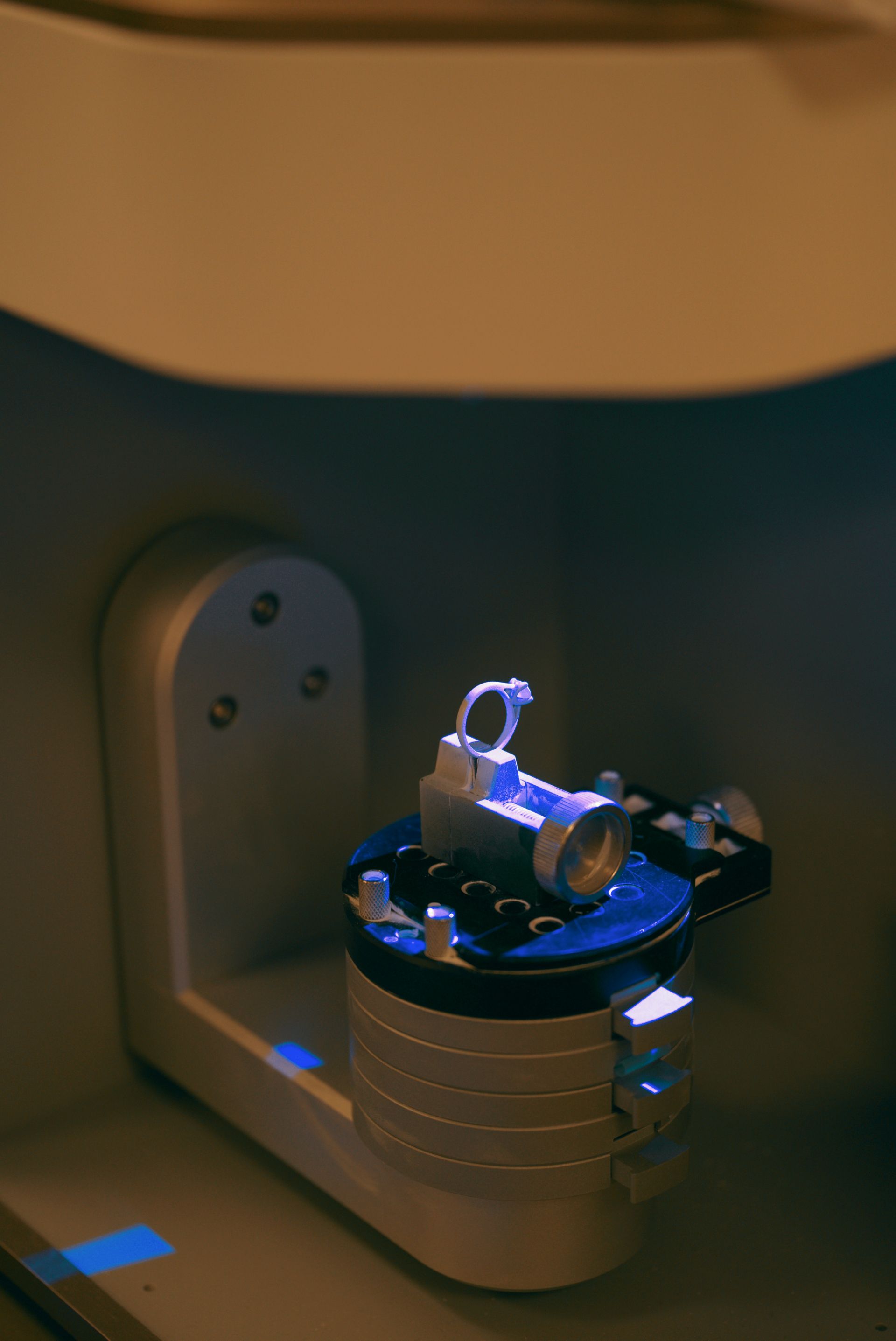

3D Jewellery Design & Prototyping

Prototyping is just one of the ways we help you bring jewellery designs to life. Working with our state-of-the-art 3D printing technology, we help you move from the screen to reality - with direct-to-print castable wax and resin prototypes.

Our 3D printing technology produces waxes with exceptional surface finishes, making clean up easier and faster, helping you transition from design to production much quicker.

Bridging the gap between digital designs and finished pieces our high-fidelity wax and resin models capture the most intricate details, perfect for casting.

Get in touch

Designed with Confidence

Work with our experienced jewellery designers in Birmingham to refine and bring your ideas to life, explore CAD for jewellery design and how we bring production-ready designs to your concept.

Your Design Journey Starts Here.Jewellery Designers in Birmingham: Why Choose Us

Supporting brands, makers, retailers and bespoke jewellers from the heart of Birmingham's historic Jewellery Quarter. We're proud to work closely with jewellery designers across the UK - from independent local makers to national brands scaling up production.

Our fully in-house design service ensures a smooth process from concept through to casting, finishing, and on-site hallmarking, with quality, consistency, and collaboration at every stage.

Get in touch

The Design & CAD Process

We know that jewellery is personal and every project is unique - it’s why we treat every piece with the care and diligent attention to detail it needs to ensure a high-level execution from start to finish.

Step 1: Initial Consultation & Design

We start by collaborating with you and your team to understand your vision, preferred materials and specifications, and our expert team then provides technical recommendations where needed. This enhances design efficiency and practicality, presenting a variety of hand-drawn designs for approval.

Step 2: CAD Modelling & 3D Digital Renderings

Our CAD team will then create high-resolution digital models, sharing multiple 2D visuals and 3D models from different angles for approval before production begins.

Step 3: Prototyping

We can produce either 3D-printed wax or resin prototypes for hands-on evaluation. This gives an opportunity to make adjustments to the fit or aesthetic before final approval.

Step 4: Transition to Production

Once approved, our in-house production allows a swift move into our casting and manufacturing facilities, with each piece optimised for production to ensure high-quality finishes.

Get Started on Your Jewellery Design

Partner with our expert jewellery designers in Birmingham and take your ideas from initial sketch to production-ready designs.

Get Expert Support at Every Step