Why Finishing Matters

Finishing is more than the final step - it’s what gives a piece its full identity. The right surface finish brings out the detail in your design, defines how it catches the light, and influences how it’s worn and perceived.

Whether it’s high-shine, matte, satin, or textured, a well-executed finish turns a cast piece into something complete - something ready for the customer, ready for the brand, and ready to last.

At Weston Beamor, we treat finishing with the same care and precision as every other stage, because it’s where everything comes together.

Get in touch

Polishing & Surface Finishing

Every piece of jewellery starts with the right foundation. Our polishing and finishing services remove surface imperfections to create a smooth, consistent base, ready for your chosen finish.

Hand Polishing

Ideal for detailed work, our team polishes by hand when designs call for extra care. It’s the best way to reach fine details and achieve a refined finish that machines can’t always match.

Specialist Surface Finishes

We offer a full range of finishes to suit different styles and preferences: matte for a modern, non-reflective look, high-shine for maximum brightness and impact, or textured effects like brushed, sandblasted or hammered for added depth and character

From concept to completion

Our team is here to help you and your customers realise your vision so, if you have something specific in mind, we’ll work with you to get it just right.

Get in touchElectroplating & Precious Metal Coatings

Electroplating enhances both the appearance and durability of your jewellery. By applying a thin layer of precious metal to the surface, we create a protective barrier that also delivers a defined, high-quality finish.

It’s a crucial step for many designs - helping reduce wear, prevent tarnish, and achieve the final look your customer expects.

Our engraving services at Weston Beamor include...

Traditional Hand Engraving

Ideal for intricate details and a classic, crafted finish. Our experienced team engraves by hand to add depth, character and uniqueness to each piece.

Laser Engraving

For crisp brand logos, monograms or fine text, laser engraving delivers precision and consistency - even with the most intricate designs. It's an ideal choice for high-volume or technically detailed work.

Inside-Ring Engraving

Add a discreet personal touch with messages, dates or initials engraved inside wedding bands, commitment rings and other special pieces.

Discover Our Full Range of Services

Beyond finishing, Weston Beamor offers a comprehensive suite of services to support your jewellery production needs, from initial concept to final hallmarking:

- Design: Bring the vision for your bespoke and full ranges to life with our expert jewellery design services, from initial sketches to full 3D renderings.

- 3D Scanning: Accurately replicate existing pieces or physical models into digital files for further modification or reproduction.

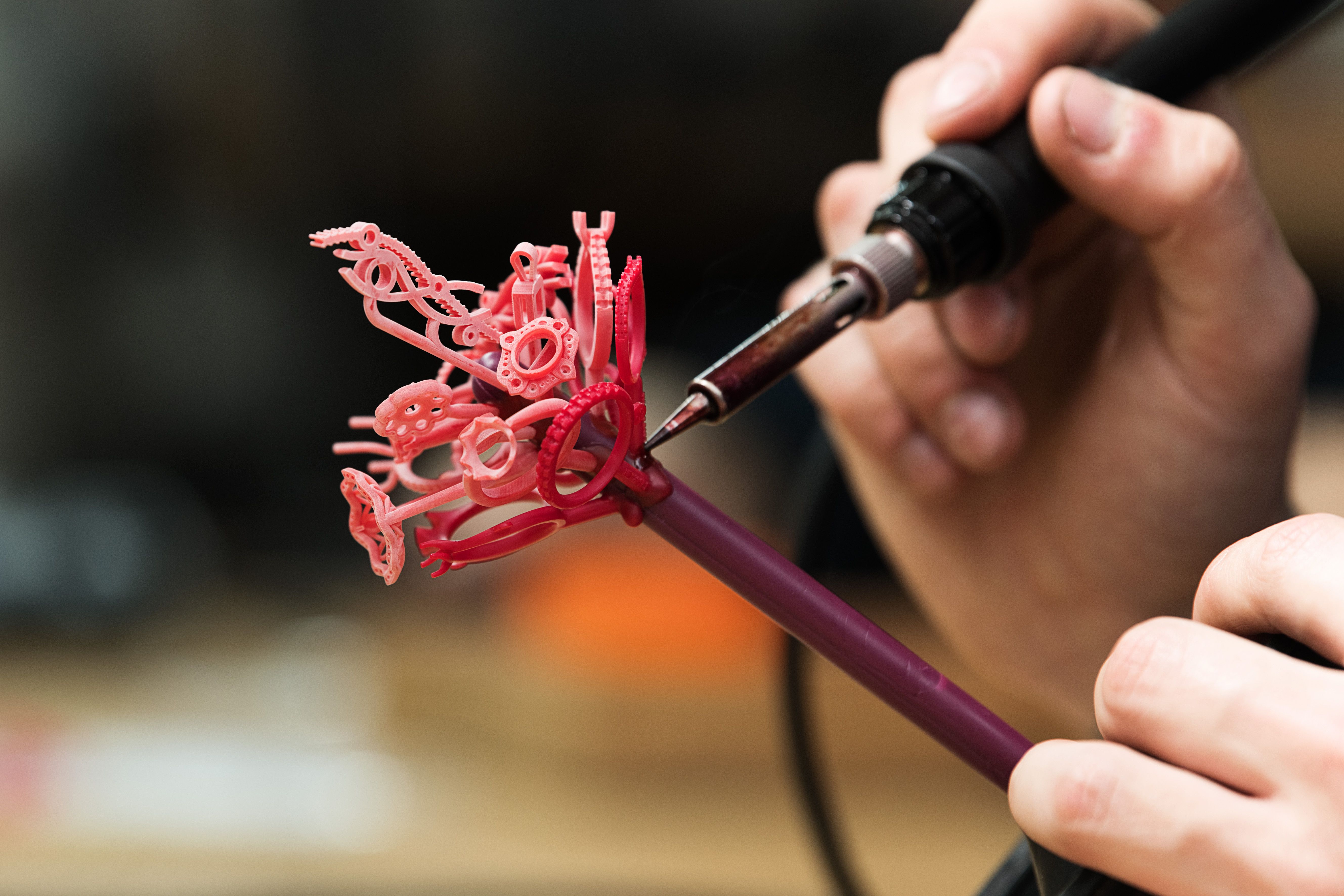

- 3D Printing: Rapidly create highly detailed prototypes and master patterns in a variety of materials using cutting-edge additive manufacturing.

- Casting: Utilise our advanced casting facilities for high-quality metal casting in gold, silver, platinum and brass.

- CAD Modelling: Develop precise and intricate jewellery designs in a digital environment, ensuring accuracy and efficiency in production.

- Manufacturing: Benefit from our extensive manufacturing capabilities, turning your designs into tangible, high-quality jewellery pieces.

- Production: From one-offs and small batches to complete ranges, our efficient production processes ensure consistent quality and timely delivery.

- Hallmarking: As Weston Beamor customer you can take advantage of our onsite suboffice provided by Birmingham assay office when you cast with us.

Finishing That Reflects Your Standards

From bespoke orders to full scale ranges, your jewellery deserves a finish that matches the care and creativity behind it. At Weston Beamor, we bring decades of experience and the latest technology together to deliver consistent, high-quality results - every time.

If you’d like to discuss how we can support your next collection or commission, get in touch. We’re here to help.