Precision in Partnership, Bringing Your Vision to Life

Our approach is built on transparent communication and genuine collaboration. Our highly skilled designers work seamlessly with our expert casting shop and onto the workshop floor, translating your vision into reality with absolute precision.

This integrated process, coupled with our commitment to your success, empowers Retailers, Brands and Designers to confidently bring the finest jewellery products to your customers.

Your End-to-End Jewellery Manufacturing Partner

Weston Beamor offers a truly comprehensive, full-service manufacturing solution, overseeing every stage of the jewellery production process. From CAD modelling to refine your initial design, to the selection of the final finish for your completed collection, we manage each step with expertise.

At the core of our operations lie our advanced in-house manufacturing facilities. We leverage state-of-the-art 3D printing, precision casting in the industry’s widest range of alloys, and expert finishing to create exceptional pieces. These capabilities are further enhanced by high-resolution 3D scanning and our convenient on-site hallmarking sub-office, provided by the Birmingham Assay Office, guaranteeing unparalleled quality and integrity at every stage.

Our fully in-house production and manufacturing capabilities ensure faster lead times, consistent quality, and competitive pricing that caters to those searching for a jewellery partner to help create collections at any scale, in addition to bespoke pieces. With Weston Beamor, there's no minimum order - just simple per item pricing, significantly streamlining your costs and simplifying your production planning.

Get in touch

How Jewellery Manufacturing with Weston Beamor Works

For over 70 years, the Weston Beamor team has refined our jewellery manufacturing methods, developing a process that delivers flexibility and creative control:

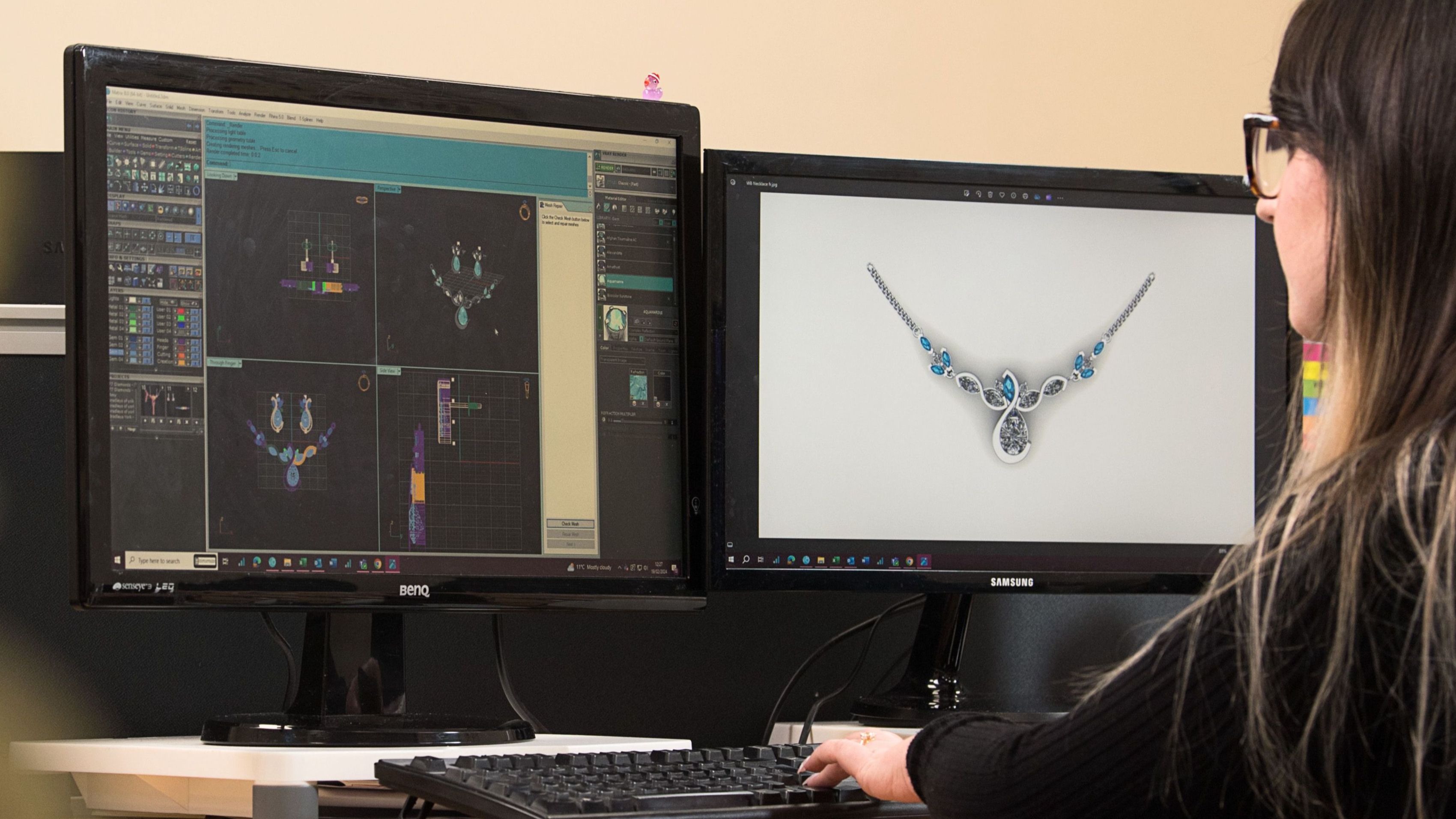

Design & CAD

Our in-house design team transforms your concepts into highly detailed CAD models.

3D Printing & Prototyping

Utilising high-resolution machines, we swiftly perfect designs through resin or wax prototypes for approval before commencing full production.

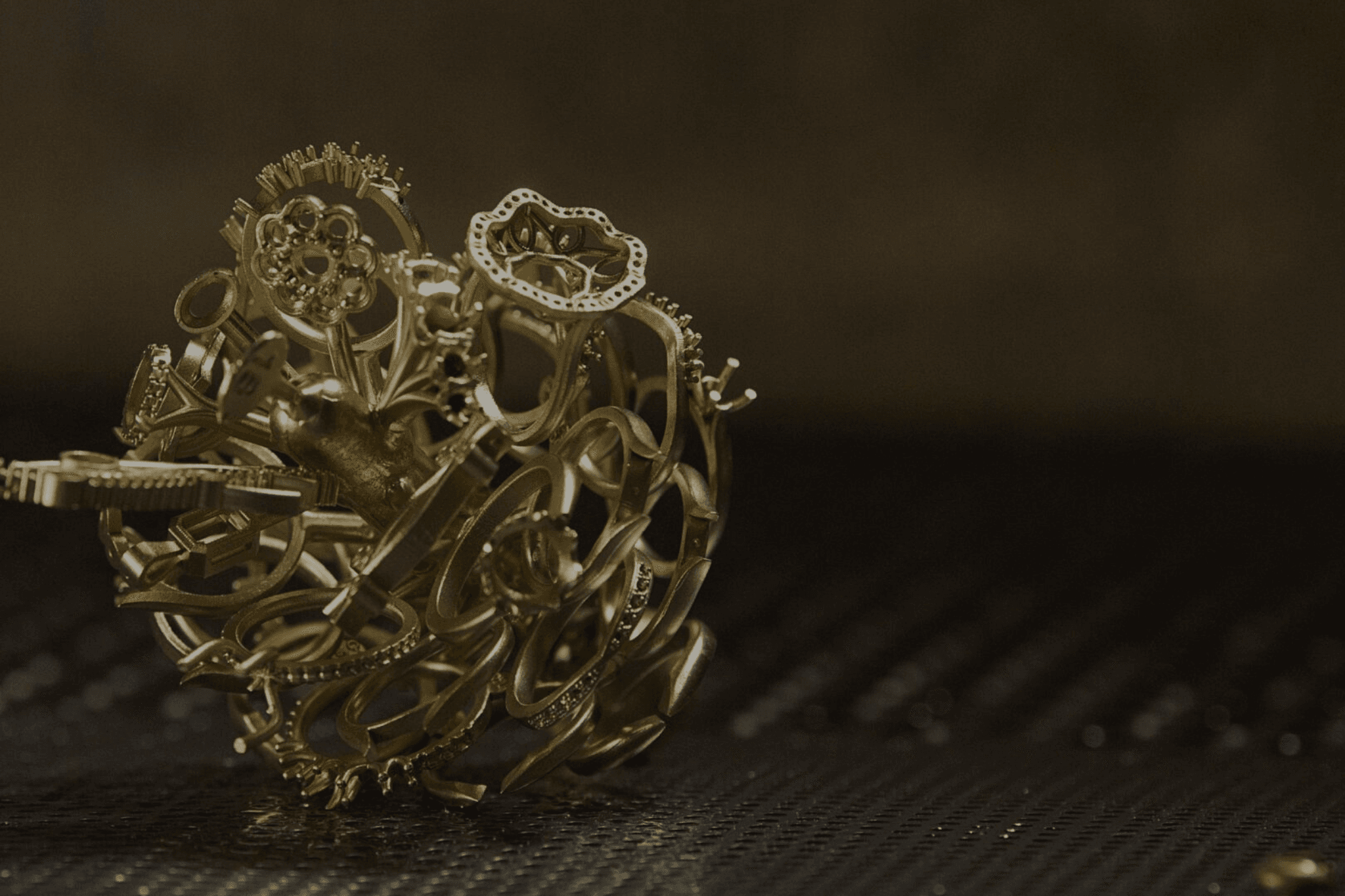

Casting

We provide precious-metal casting using lost-wax methods, ensuring fast, consistent turnarounds with a wide range of alloys.

Assembly & Finishing

From simple to complex, our expert team are here to help with everything from setting and polishing to assembly.

Quality Control

Supporting retailers, designers and brands for over 70 years, our rigorous final inspections guarantee quality and consistency.

Hallmarking

On-site hallmarking service, provided by the Birmingham Assay Office sub-office.

Our Commitment to Sustainable Jewellery Manufacturing

Sustainability sits at the core of everything we do at Weston Beamor, and we know that choice matters. We offer a comprehensive range of responsibly and traceably sourced metals, including 100% recycled, Fairtrade, and Single Mine Origin (SMO) gold, empowering you to align your collections with social and environmental standards.

Whether you're an independent designer looking to create something bespoke or an established retailer expanding your range, we are here to support with a variety of sustainable options and expert guidance at every stage of your project.

Sustainability

Effortless Design Submission with Full Pricing Transparency

Our intuitive customer portal allows you to directly upload your CAD files or select from your own extensive mould library. With fast quotations available after design submission, we ensure complete transparency from initiation to completion, allowing you to meet timescales and demand with ease.

Speak to our expert team

Whether you’re a small designer looking to launch your first collection or a high-street name looking for a partner that delivers every time, Weston Beamor’s jewellery manufacturing capabilities are here to bring your ideas to life.

Get in touch