Sustainable Jewellery Manufacturing with Weston Beamor

Sustainability in jewellery is complex, but that doesn’t stop us from doing better every day. From offering recycled, SMO, and responsibly sourced metals across casting and bespoke solutions to reducing waste and improving traceability, we’re committed to making choices that support a more ethical, transparent, and responsible industry. Because how we make jewellery matters, not just to the businesses we work with, but to the people and places behind every piece.

As a certified member of the Responsible Jewellery Council (RJC), Weston Beamor is independently verified for our commitment to sustainability and ethical craftsmanship. We provide retailers, brands, and designers with the assurance that their jewellery aligns with the values of today's discerning consumer. From responsibly sourced and recycled metals to the implementation of low-impact manufacturing techniques and SMO gold, we ensure every piece meets the most stringent standards of integrity and sustainable jewellery manufacturing - and we’re not stopping there. We’re committed to finding new ways to improve, exploring technologies and solutions to continue to reduce our carbon footprint.

Get in touchOur Commitment to Sustainability, in Practice

Since 1947, Weston Beamor has been helping retailers, brands, and designers make exceptional jewellery. Today, we work together to give all our partners the widest choice of responsibly sourced alloys - helping you to make jewellery that's not just beautiful, but sustainable.

Recycled Materials

We offer 100% recycled gold and silver options, as well as platinum options containing 55% recycled materials, significantly reducing the environmental impact associated with newly mined metals.

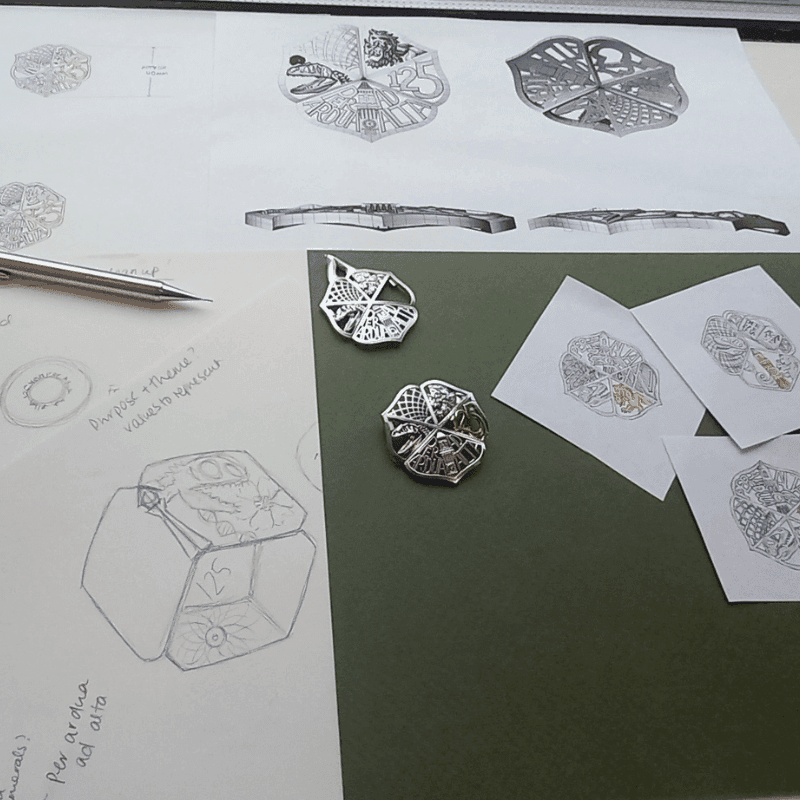

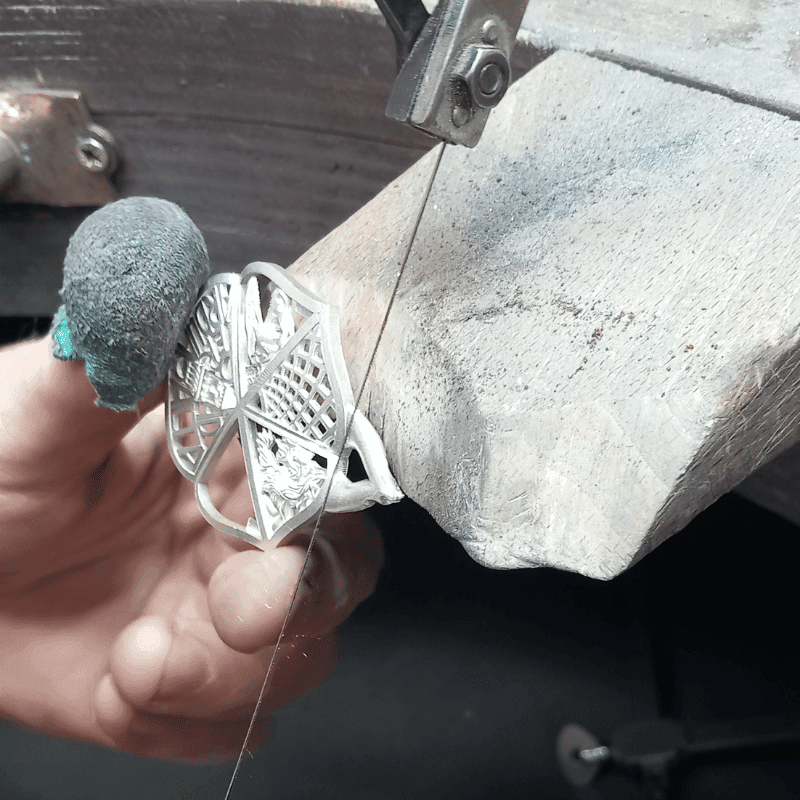

Integrity in Making

Our team of jewellery experts balance traditional, time-honoured skills with modern, sustainable, and traceable practices to reduce waste and energy at every step.

RJC-Certified Ethical Standards

Our adherence to the rigorous standards of the Responsible Jewellery Council means our clients can trust our ethical and sustainable manufacturing processes.

Traceable Supply Chain

Wherever possible, we operate a traceable supply chain for our materials, ensuring accountability and transparency throughout the supply chain.

Energy-Efficient Manufacturing

We are committed to reducing our environmental footprint through the prioritisation of energy-efficient processes, the use of solar panels at our production facility to minimise our carbon footprint, and by providing green packaging options that are able to be recycled.

Support for Fair Labour Practices

The welfare of everyone involved in the creation of our jewellery is paramount. We pay the real living wage, ensure safe working conditions, and prioritise respectful treatment throughout our operations and supply chain.

Future Facing

The jewellery industry still has strides to make in order to become as sustainable as possible, and we’re open, honest, and committed to finding ways to improve our processes for the betterment of our planet.

Sustainable & Ethical Production Services

Weston Beamor's commitment to sustainability across the jewellery industry is woven into every aspect of our production services, offering peace of mind for retailers, brands and designers who prioritise ethics and responsibility.

Ethical & Sustainable Material Sourcing

100% Recycled Precious Metals

We proudly offer 100% recycled gold and silver. Our platinum contains a minimum of 55% recycled material, with any virgin material sourced exclusively from LBMA approved and RJC accredited sources. This significantly reduces the need for new mining and its associated environmental impacts.

SMO Certified

We source from certified mines that adhere to fair wages, safe working conditions, and responsible environmental practices, directly supporting mining communities.

Traceable Provenance

We strive to ensure our alloys are free from minerals sourced from conflict areas - we pay a premium to source the cobalt used in our platinum castings from Canada, providing your customers with confidence in the ethical and sustainable origins of their jewellery.

Ethical Diamond & Gemstone Sourcing

We work with trusted and reputable suppliers to ensure our gemstones are sourced mindfully. This includes avoiding gemstones sourced from CAHRA countries, as well as sourcing diamonds that comply with the Kimberley Process and other relevant standards.

Get in Touch

Low-Impact, Energy-Efficient Production

We are actively working towards reducing our carbon and environmental impact through continuous improvements in our manufacturing methods.

Energy-Efficient Equipment

Across our business, we’re consistently investing in lower energy equipment. New furnaces in the casting workshop consume 40% less electricity than previous models, and we've optimised their use for different alloys to further reduce electrical requirements.

Reduced Water Consumption

We’ve also reviewed and continue to review our water consumption and wastage, implementing changed practices and a 15% reduction in usage in 2024. We’re not stopping there - with further reductions targeted for the years ahead.

Renewable Energy

Our solar panel installation provides over 33% of the energy for our building, significantly reducing our reliance on the grid.

Closed-Loop Manufacturing

We operate a robust closed-loop manufacturing process. All metal lost through the stages of manufacture – from water and air filters to the robot hoover collected gold specs – is captured and reclaimed. This closed loop process ensures no material is wasted.

Optimised Metal Use

Improved polishing techniques reduce the removal of metal that would otherwise require refining.

Energy-Efficient Lighting

As part of our ongoing works we have installed energy-efficient lighting throughout our business.

Responsible Packaging & Supply Chain Management

Our commitment to sustainability extends beyond production to how our jewellery is delivered and our broader supply chain.

Eco-Friendly Packaging

We are actively moving from plastic packaging to sugar cane-based packaging, which is recyclable. We will continue to reduce plastic usage in all our packaging and logistics processes.

Supply Chain Audits

All our suppliers are externally audited by an independent audit authority, in addition to regular visits by Weston Beamor staff.

Prolonging Product Life

We provide a repair and refurbishment service to extend the life of our jewellery and reduce items going to refining.

Electric Company Vehicles

We are migrating our company car fleet to electric vehicles, actively working to calculate and reduce our diesel and petrol kWh consumption.

Talk to the Team

Compliance with Global Ethical & Product Safety Standards

Weston Beamor is proud to uphold and exceed industry standards for ethics, sustainability, and product safety.

Responsible Jewellery Council (RJC) Certification

This demonstrates our comprehensive compliance with environmental, social, and ethical best practices.

UK Assay Office Hallmarking

Our on-site sub-assay office provides independent verification of the purity of our precious metals.

Fair Labour Practices

We ensure that every individual who works for Weston Beamor is treated fairly, respectfully, and works in safe conditions.

SMO Partner

Weston Beamor are a proud SMO Manufacturing Partner.

Product Safety Regulations

All of our products comply with the General Product Safety Regulations.

REACH & Cobalt Safety Compliance

All products and alloys are randomly selected and tested by the Birmingham Assay Office to comply with REACH and cobalt safety limits.

Ongoing Surveillance

Every metal and alloy is screened through a product sampling process and tested as above, as part of an ongoing surveillance program to ensure continuous compliance.

100% Quality Control

All products undergo a 100% QC inspection before leaving our premises.

Ethical and Sustainable Jewellery Manufacturing Solutions

Choosing sustainable and ethical jewellery production with Weston Beamor offers significant advantages for a range of businesses...

Retailers & Jewellery Brands

94% of jewellery customers believe jewelry brands should be more transparent about the origin of the raw materials they use, meaning that it’s more important than ever for retailers and jewellery brands to meet the growing consumer demand for responsible jewellery production.

Designers & Independent Creators

Sustainable jewellery is no longer a niche - it’s a growing expectation. For emerging designers and independent makers, embracing ethical materials and transparent sourcing is a powerful way to build trust, add value, and align with what modern customers care about most.

Luxury & Bespoke Jewellery Houses

Ethical sourcing is fast becoming a hallmark of modern luxury. Today’s customers don’t just admire beautiful design - they want to understand the story behind it. By championing transparency and responsible sourcing, bespoke houses can deepen customer loyalty, reinforce brand prestige, and offer pieces that feel as good as they look.

Make a Statement with Sustainable & Ethical Jewellery

Jewellery sustainability is not a trend; it is a fundamental commitment to shaping a better future for the entire industry. At Weston Beamor, we’re dedicated to providing choice across all our casting and manufacturing solutions, empowering retailers, brands and designers to meet today’s standards and build a responsible legacy they can be truly proud of.

If you are seeking a trusted partner to help you create beautiful, ethically responsible jewellery, work with us at Weston Beamor. Our deep-rooted commitment to sustainability, transparency, and exceptional craftsmanship ensures that every piece is as responsible as it is beautiful.

Discover how our ethical and sustainable jewellery services can help you create jewellery that makes a positive impact – for your customers and for the planet.