Comprehensive National and International Jewellery Services from the Heart of Birmingham

We are committed to delivering precision and consistency across every stage of the jewellery manufacturing process, from CAD modelling and casting to finishing and hallmarking via our on-site sub-assay office. We handle everything in-house.

From independent designers to major brands and bespoke retailers, our integrated production process significantly helps to reduce lead times and minimise handling risks. Wherever possible, we incorporate ethical and environmentally conscious practices, ensuring our jewellery services produce pieces that not only look good but also do good.

Get in touch

Jewellery Casting

As one of the most trusted jewellery casting houses in the UK, we proudly pioneered lost-wax casting and have been providing expert, trusted casting services from the heart of Birmingham ever since.

We work closely with luxury brands, independent designers, and retailers to deliver castings that meet the exact needs of each project, guiding metal selection and ensuring every detail is cast with absolute precision. Our in-house expertise guarantees a smooth transition from wax or resin models to a flawless precious metal piece, ready for the next stage of production.

Explore more

Jewellery Design

Our in-house design team collaborates with designers, retailers, and brands to transform their initial concepts into production-ready realities. Whether we're working to create sketches from your concepts or detailed 3D designs that bring your ideas to life, our specialists treat every project with meticulous attention to detail from the first sketch to the final polish.

This service is the perfect start to a project, ensuring your creative vision is a technically sound blueprint ready for our CAD, printing, and casting teams to bring to life.

Explore more

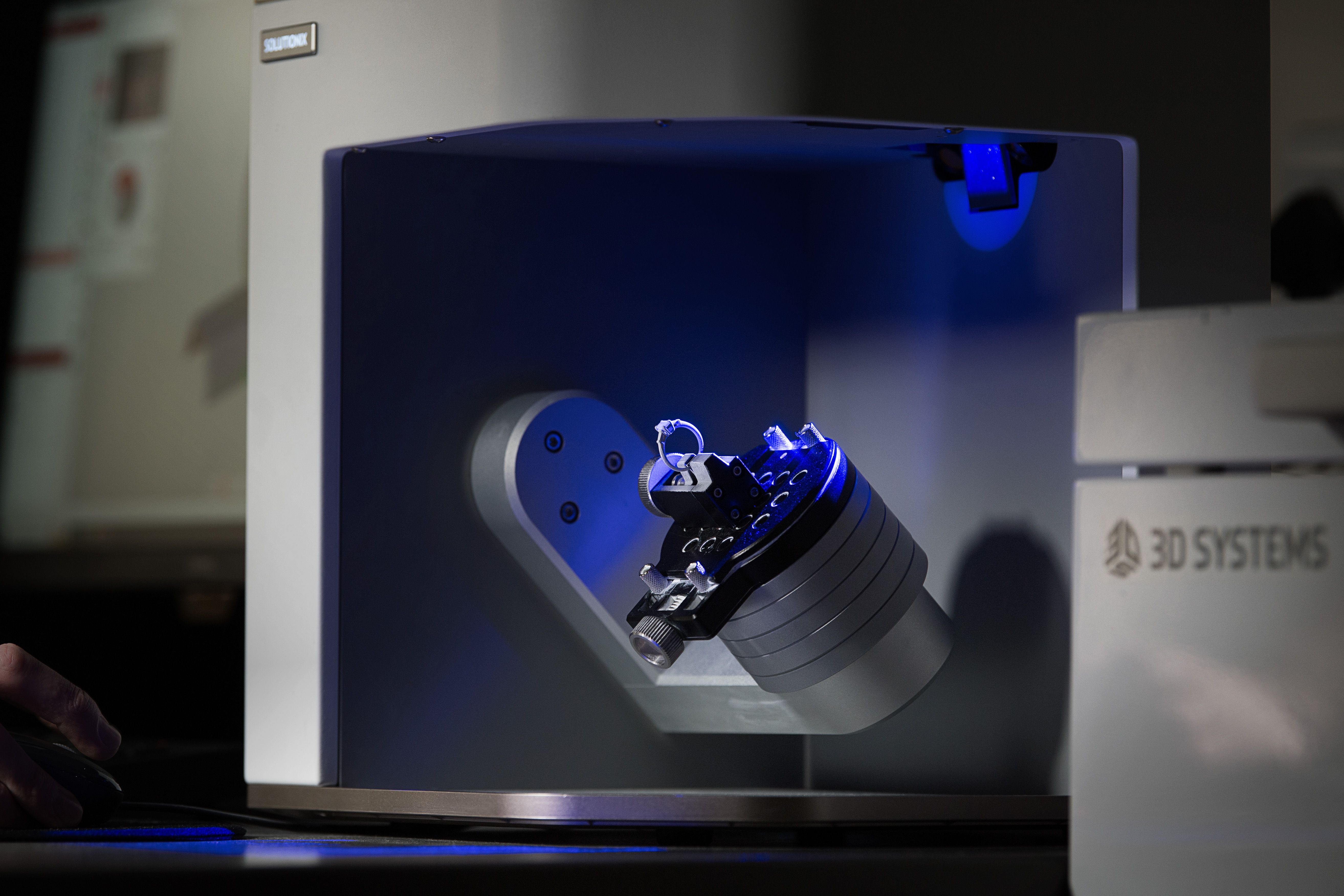

3D Scanning

Our structured approach to 3D scanning begins with a detailed consultation to understand your needs, followed by an ultra-high-resolution scan that captures every detail. This allows for a seamless transition from handcrafted models and existing pieces to digital prototypes, improving production efficiency while maintaining complete creative control.

Whether you need to scan an engagement ring to create a perfectly fitted wedding band or capture a 3D object for recreation or scaling in CAD, our service provides the precision and accuracy required for flawless production.

Explore more

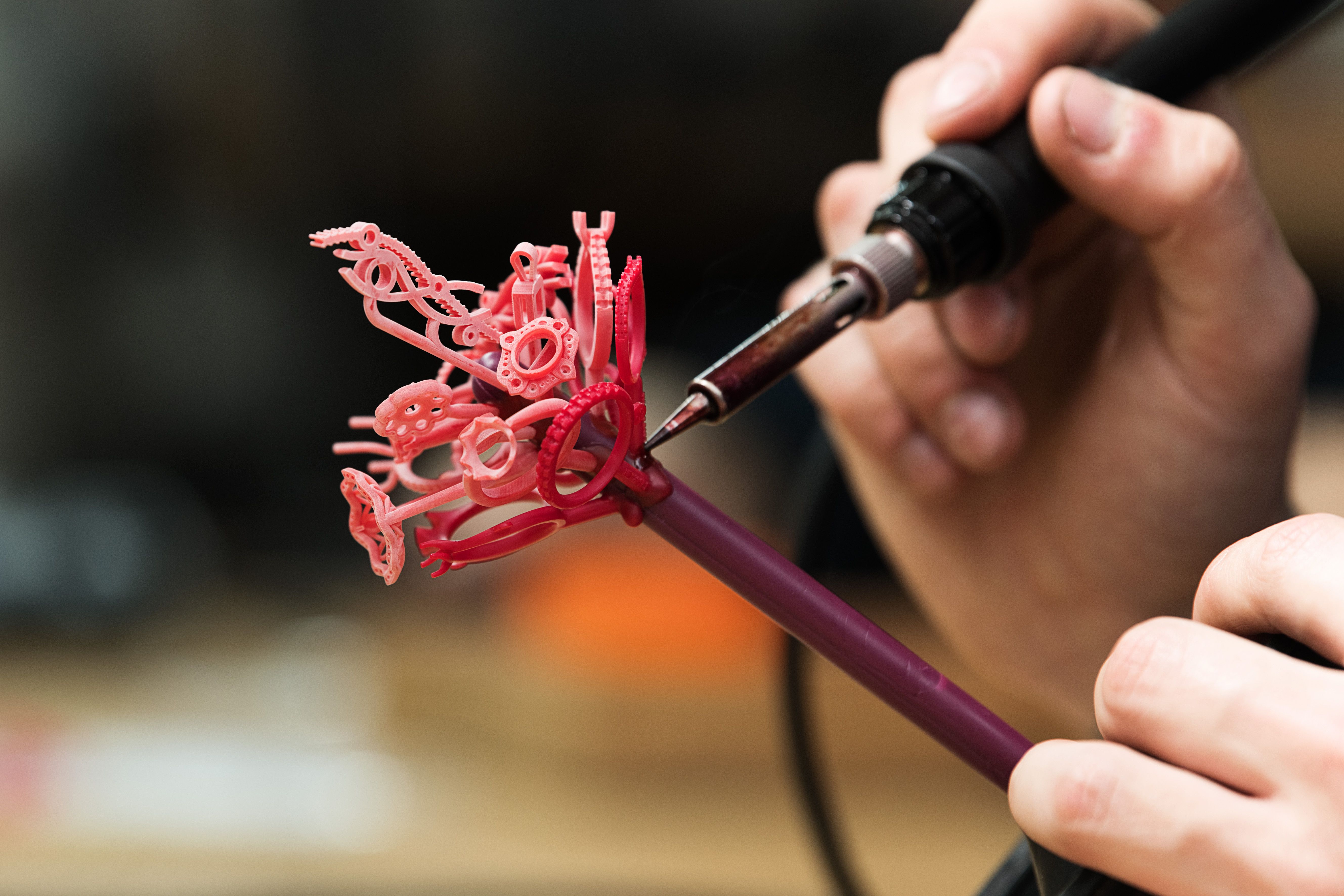

3D Printing

Our 3D printing service empowers retailers, brands, and designers to develop unique, personalised jewellery pieces with exceptional detail and accuracy. We utilise industry-leading 3D printers to create models with a perfect surface finish and superior dimensional accuracy. We offer models in both wax for direct casting and resin for creating moulds, providing an ideal foundation for production.

Our integrated process and expert pre-print analysis ensure your designs are executed with precision, giving you the confidence that your creations will be delivered to market on time and to the highest standard.

Explore more

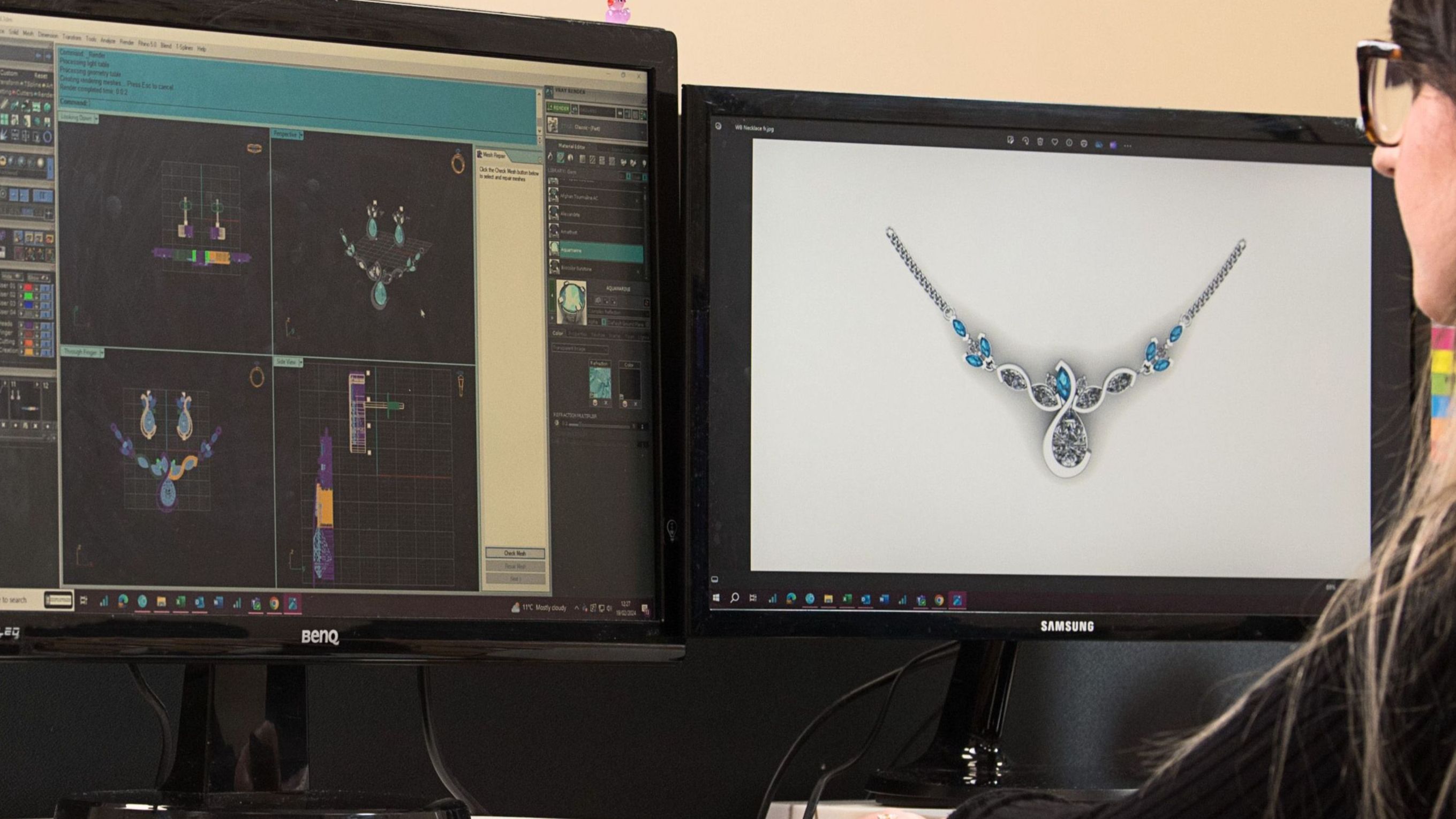

CAD Modelling

Our in-house CAD team creates highly detailed digital models that allow you to refine your designs for settings, material compatibility, and finishing details before moving into casting. This collaborative process provides both 2D visuals and 3D renders for your approval, ensuring manufacturability and visuals true to your design vision.

By partnering with Weston Beamor, you gain access to a team of experts who will help you perfect your designs, making the transition from concept to creation seamless and efficient so you can get your products to your customers as soon as possible.

Explore more

Jewellery Manufacturing

Whether you need bespoke jewellery manufacturing for a single unique piece or the production of thousands of units, every item is created with the same diligent attention to detail.

Our facilities, based in the heart of Birmingham’s historic Jewellery Quarter, bring together advanced 3D printing, casting, stone setting, and finishing, all overseen by a skilled team of craftspeople and production specialists who ensure consistency and quality at every stage.

Explore more

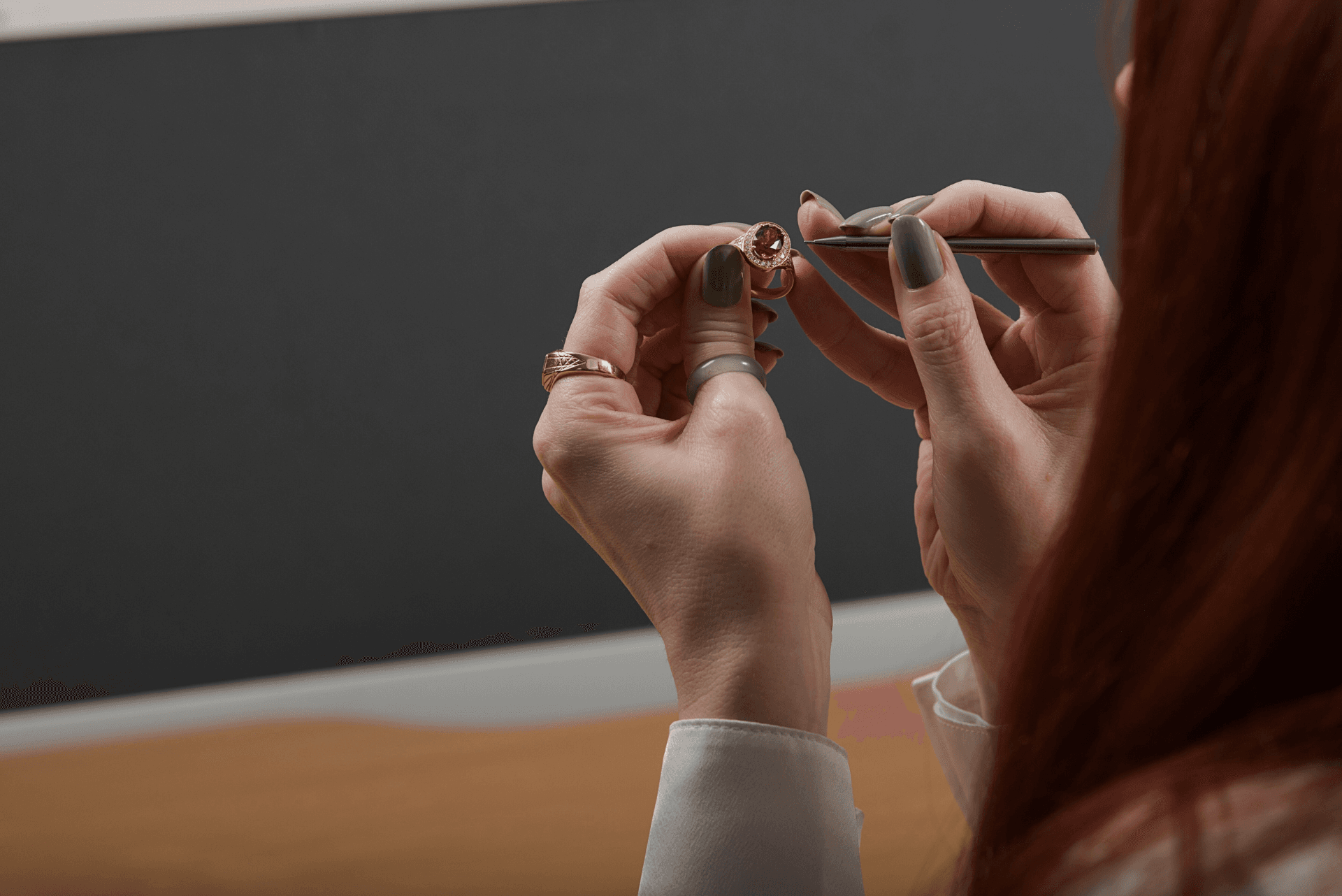

Jewellery Finishing

From polishing and plating to engraving and stone setting, our in-house finishing team brings decades of experience to every piece. With strict quality control at every stage, we guarantee a consistent finish that meets the highest standards — whether for a single item or an entire collection.

Our meticulous attention to detail, combined with deep technical knowledge, ensures that your products always meet your high standards.

Explore more

Jewellery Hallmarking

Our hallmarking process is simplified with an on-site Sub-Assay Office, provided by the Birmingham Assay Office. This not only ensures every piece—whether gold, silver, or platinum—meets UK Hallmarking Act regulations, while streamlining production by removing the need for external paperwork and shipping.

This in-house capability is just one of the ways we help our customers with seamless service from start to finish.

Explore more

Sustainability

We are committed to shaping a better future for the jewellery industry by implementing sustainable and ethical production practices wherever possible.

We offer recycled and Single Mine Origin (SMO) gold, and our commitment to transparency and traceability helps retailers, brands, and designers meet modern environmental, social and governance standards. We believe that how we make jewellery matters, and we are dedicated to providing you with the choices that support a more responsible and conscientious industry.

Get in touch